Desultory Droppings from October 2021 ACG Newsletter

Compost for the cranium

Hose Repair – experience, insights and an easy, quick and cheap solution

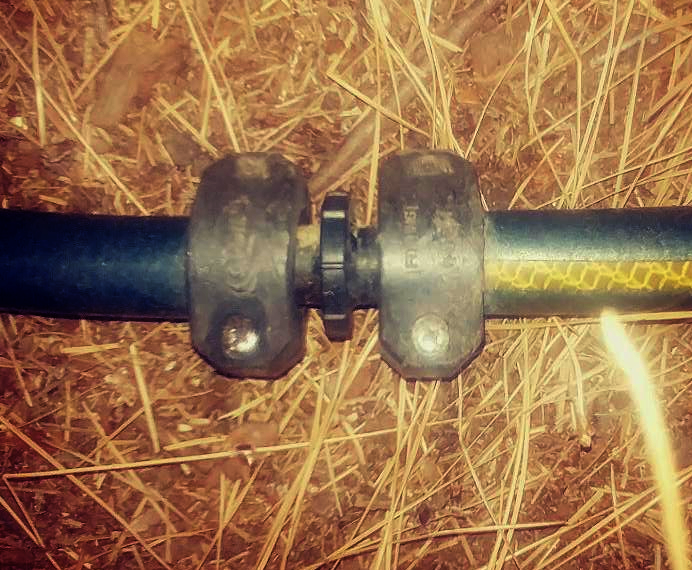

One way to fix a garden hose leak is to cut the hose, clean up the ends and splice them together with a store-bought “hose mender” fitting which includes a rigid sleeve inserted into the hose ends and clamps on either side. This works well but involves time and expense and leaves a large fixture in the middle of the hose which can be awkward and may prevent pulling it through things.

The traditionally recommended way to tape a garden hose leak is to wrap overlapping turns of tape, first one way, then the other, in both directions far past the rupture itself. This takes a lot of tape and time and is not guaranteed to work every time. Better solutions exist now.

A very impressive hose repair tape is available from different sources. Variously called “Rescue Tape” or “Self-fusing silicone tape,” it does indeed fuse to itself to make a watertight bond. However, in an experiment, when subjected to constant pressure – water turned on with closed valve on the end of the hose – its tensile strength was not adequate and it formed a great aneurysm, a gradually expanding balloon of water which did give way eventually.

It has been whimsically asserted that, with enough duct tape and something to stand on, anything can be fixed. Duct tape does have the tensile strength to handle water pressure but, on its own, often doesn’t produce a leak proof patch. A silicone tape patch covered with duct tape for strength did solve the problem temporarily but is both resource and time intensive and it did eventually start to leak out the ends. Still not an ideal solution.

The problem with patches tends not to be flaws in the wraps of tape themselves, particularly if properly overlapped. Most often, water is seen shooting out of the end of the patch, requiring the patch to go on and on for a great distance. A hose clamp is one solution but it is hard to deploy a hose clamp in the middle of a long length of hose and it is also necessary to acquire a one.

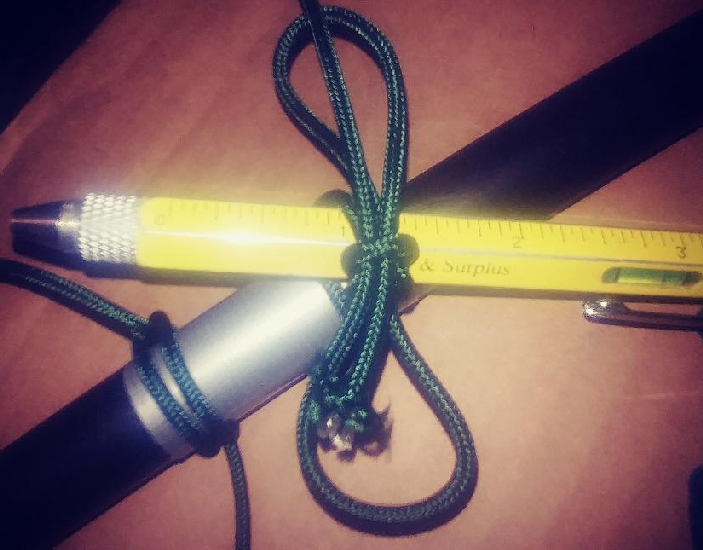

A cheap, novel and inexpensive solution is to tie an ad hoc hose clamp with a piece of cord. Yes, a constrictor knot tied with strong, non-slippery cord does the job nicely (see how to tie a constrictor knot). It can’t be cinched as tightly by pulling as can be achieved by screwing a hose clamp, but that shortcoming can also be overcome. If one continues the ends of the cord around the hose after tying the constrictor knot and ties them together (with a bow for easy release) over a shaft – screwdriver, pen etc., then the knot can be cinched dramatically, much like a tourniquet, by turning the shaft. Care must be taken not to break the cord which is easier than one would think, even if it is far too strong to break by hand pulling. When fully cranked, the two ends can then be cut or tied together. An experiment applying such knots to the ends of a duct taped patch was entirely successful. This solution does however depend upon solid structural resistance of the hose itself as, unlike using the hose mender fixture, there is no rigid internal sleeve to clamp down upon.

This discovery leads one to ask the big question: When patching a localized leak and applying tied hose constrictions, is there any need to do an overlapping wrapping job at all? A single or double pass of two-inch-wide duct tape wound over the leak in a matter of seconds with tied constrictions on either side could be a simple, minimal and ideal solution to hose leaks. Duct tape on its own may lose adhesion and come unstuck over time, but when tied down this way, that problem is also solved. The experiment has been successful so far, but has not yet withstood the test of time.

What cord is best to use is still an open question. Durability is certainly a factor and other obvious alternatives such as wire or zip ties clearly present deterioration and rust issues along with the fact that when coiling and sliding along a hose, one is likely to discover that they are not particularly friendly to the hands.

100 lb test 3/64 inch microcord was another experiment, but when it was cinched down hard it bit through both duct tape and hose, producing a new leak. Cotton, jute, nylon, polyurethane, paracord are all options but all will deteriorate and some suffer from photodegredation. All of these appear to be viable options and only time will tell.

Conclusion: It works! But the hose must be strong enough to resist the tied constrictions; softer spongy hoses will not allow for a good clamping job. The tying material must be strong, and broad enough not to cut through tape and hose.

Another layer of duct tape to protect the cord from sun and weathering would probably extend the life of the patch and, as the hose has already started to have leaks, the patch might last longer than the hose. As Garrison Keillor’s National Duct Tape Council put it: When it really comes down to it, isn’t all repair temporary?